- Broaching

- Broach Tooling

- Specialty Tooling

- Slotting & Keyseating

- EDM

- CNC Machining

- Secondary Operations

- Contact Us

As a leading broach tooling manufacturer, V W Broaching Service is known for its broaching tooling and manufacturing services. A broach is sometimes referred to as a broach cutting tool, a broach tool, or a broaching tool. The complement of a broach and the fixtures that hold it, and/or the part that it is cutting, is referred to as broach tooling. Broaches are classified as multiple-point cutting tools, in that they have two or more cutting edges.

Broaching tools are designed with a series of teeth arranged in rows. Each row of teeth is successively larger and to the shape desired, than the previous row. The entire cut is divided over all rows of teeth, so that each broach tooth removes only a few thousandths of an inch of material. The broaching tool is pulled or pushed through or past the part to be cut; or in some cases the broaching tool is held stationary while the part is pulled or pushed through or past the broach. In a typical broaching operation the starting hole of the part to be cut is approximately the same size as the first tooth of the broach. The last tooth is the exact shape and size of the desired cut.

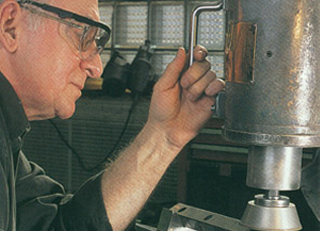

Broaching tools are first ‘roughed in’ to the approximate size, using a lathe in the case of round broaches, or a traditional milling machine in the case of flat broaches. All dimensions, including the actual teeth are finished to within .030 inch of final size. For those broaches requiring mounting holes, holes are drilled and tapped at this point. The broach is then heat-treated. Hardness may vary according to the type of material that is being cut, but typically ranges between 65 and 67 HRC. After heat-treating, the broach cutting tool is finish ground, using a cylindrical grinder for round, or a surface grinder for flat broaches. All surfaces on the broach are ground to size, including heights, widths and tapers. The broach is then moved to a sharpener, where the teeth are sharpened and backed off, and chip breakers are ground, if required. Finally, if the industrial broaching tool is a spline, the broach is moved to a spline grinder for finishing.

Material used in the manufacture of broach cutting tools varies according the demands on the broach, such as the length of cut, and the type of material to be cut. However, in typical cases only the highest quality tool steel is used, such as PM-M4.

V W Broaching Service has one of the largest inventories of stock broach cutting tools in the world. These broaches are available to be used on our customers’ jobs at no additional charge to the customer. V W Broaching Service maintains and replaces these broaches as needed, and at its own expense. There are thousands of broach tools available, including various sizes and lengths of: round, square, hexagonal, octagonal, rectangular, oval, keyway, round body keyways, multiple keyways, inverted keyways, serration broaches, D broaches, double D, spline, inverted spline, pot broaches of many varieties, and many other specialty broaches. Please contact V W Broaching to determine whether we have a stock broaching tool to fit your application.

A typical broach tooling package may consist of: a fixture to hold the broaches (in the case of surface and pot broaches), a fixture to hold the part, a broach horn (a fixture used to support the broach in a concentric hole – such as in keyway broaching), and other fixtures that might be required to move or index the part for a second broaching operation. We design and manufacture all components of the broach tooling package.

V W Broaching Service is pleased to provide in-house broach cutting tool design and services, using the most sophisticated CAD methods available. Design services are provided at no charge for our customers. Typically our customers provide us with a blueprint of the part, and we design the broaching tool to meet the finished specifications. However, we can also reverse-engineer the part from a sample provided, and design the broach cutting tool from the sample. Send a drawing today for a quote on our broaching tool design services!

V W Broaching prides itself in quick turnaround for all of your broach sharpening and reconditioning needs.

View More »

View More »

In-house broach design and fabrication facilities: none of our tooling needs are subcontracted!

View More »

View More »

Broach tooling is most often as customized as the workpiece that it will cut.

View More »

View More »

The broach tool is the vital part of any operation. They must be made to the precise size of the final cut desired.

View More »

View More »

Ask Us About Broach Tooling

* indicates required field