- Broaching

- Broach Tooling

- Specialty Tooling

- Slotting & Keyseating

- EDM

- CNC Machining

- Secondary Operations

- Contact Us

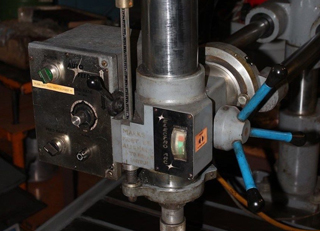

For breakdowns, small quantities, hardened material, or complex forms in large quantities, V W Broaching provides in-house Electrical Discharge Machining Services. Utilizing CAD to design the precise path taken by a conductive wire, one of our EDM machines can be up and running on your job in minutes - with no tooling costs! Our state-of-the-art Mitsubishi machines provide extremely precise work, with tolerances held to within .0002.

Electrical Discharge Machining finishes are superb - down to RMS 12 on most materials; and any conductive material can be cut, including hardened and exotic materials. Using both non-submerged and submerged cutting technology, we have tapering capability for conical or isometric radii and shapes.

The Electrical Discharge Machining Division of V W Broaching Service takes pride in our ability to turn your problem parts around quickly - very often within 24 hours!

Contact VW Broaching to learn more about Electrical Discharge Machining (EDM)!

Request a QuoteDisintegrating is the historical precursor to what is now known as electrical discharge machining(EDM)

View More »

View More »

A method of cutting conductive material. Wires disintegrate materials in a controlled manner

View More »

View More »

Ask Us About EDM

* indicates required field