- Broaching

- Broach Tooling

- Specialty Tooling

- Slotting & Keyseating

- EDM

- CNC Machining

- Secondary Operations

- Contact Us

High speed broaching is usually employed to cut smaller parts, and can compete quite favorably with the milling process, while still holding extremely close tolerances.

V W Broaching Service has a wide variety of high speed broaching machines, each machine distinguished by its stroke, speed, power, and loading mechanism.

High volume broaching refers to the type of machine that is used to broach a piece part. A high speed broaching machine is simply a vertical surface broaching machine, in which the ram typically has less mass, less stroke, and has a smaller length of cut.

In reducing the mass of the machine, ram, and associated fixtures, the ram is able to travel at much greater speeds. While typically used to cut external slots, shapes and forms, internals can also be cut. These machines adapt well to high volume production. Contact us for to learn more about our high volume broaching services.

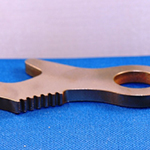

High Speed Broaching Image Gallery

There are no images available matching all of your filter selections. Please unselect at least one filter to display matched images.

Ask Us About High Speed Broaching

* indicates required field