- Broaching

- Broach Tooling

- Specialty Tooling

- Slotting & Keyseating

- EDM

- CNC Machining

- Secondary Operations

- Contact Us

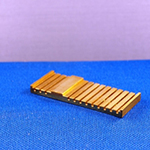

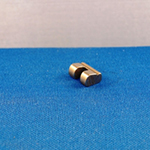

V W Broaching offers high quality straddle broaching services. Straddle broaching refers to cutting more than one surface of a piece part in one stroke, by using multiple broach tools which span or straddle the part. It is most often employed in smaller parts requiring mirror cuts or equal cuts to be made on a single part.

Broaching tools, mounted in holders, and affixed to the ram of a high speed broaching machine, can be used to cut virtually any surface of a part in the same plane, and is limited only by the ability to hold the part firmly enough to withstand the broaching process. An example of a straddle broaching application would be forming a square external shape on the end of a cylindrical valve stem. The first two surfaces are cut, the part is then indexed at 90 degrees and the final two surfaces are cut. Straddle broaching is typically fast, while still being able to hold very close tolerances.

Straddle Broaching Image Gallery

There are no images available matching all of your filter selections. Please unselect at least one filter to display matched images.

Ask Us About Straddle Broaching

* indicates required field