- Broaching

- Broach Tooling

- Specialty Tooling

- Slotting & Keyseating

- EDM

- CNC Machining

- Secondary Operations

- Contact Us

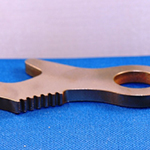

Vertical broaching refers to the type of machine that is used to broach a piece part. Vertical broaching is typically used to cut external slots, shapes, and forms. Each application of vertical broaching usually consists of a custom made tooling package, and a fixture to hold and secure the piece part. An example of a vertical broaching application would be cutting a deep slot in a large industrial valve stem.

V W Broaching Service has a wide variety of vertical broaching machines, each machine distinguished by its stroke – which defines the length of cut – and its power - which defines the size of cut the machine is able to make.

Vertical broaching machines come in many varieties and adaptations, but in general any machine in which the ram is mounted vertically, instead of horizontally, is classified as a vertical broaching machine. In the case of surface broaching, the ram, which carries its broaching tools mounted in holders, typically moves past the piece part. The piece part is secured in a fixture using hydraulic or mechanical clamps. Some traditional vertical broaching machines are dual ram, meaning that there are actually two rams mounted on the same machine, and sharing the same hydraulic and mechanical systems. In many cases the part is secured in a shuttle table or swing table, so that the operator can load one piece to be machined, while the other ram is cutting another piece at the same time. Dual ram vertical broaching machines can also be used to cut two or more successive operations on the same part.

Vertical broaching machines can also be used to cut internal shapes and forms, and can perform very much like traditional horizontal machines. In each case either the piece part is secured while the broaching tool moves past it, or the broach itself is secured while the piece part travels on a table. The former type of machine can be either of the vertical pull-down or pull-up variety (referring to the motion of the broaching tool). The latter is typically referred to as a table-up vertical broaching machine.

Vertical Broaching Image Gallery

There are no images available matching all of your filter selections. Please unselect at least one filter to display matched images.

Ask Us About Vertical Broaching

* indicates required field